Astm A106b High precision txias dov seamless steel yeeb nkab

High-precision txias-draw precision steel yeeb nkab yog ib hom tshiab steel yeeb nkab, uas nws lub ntsiab feature yog siab precision.Feem ntau ob-cov menyuam mills thiab peb-cov menyuam mills ntau lawm ntawm ob txheej txheem ntau lawm, peb-cov menyuam zeb ntau lawm ntawm txias dov seamless steel raj precision siab dua, tuaj yeem tswj tau nyob rau hauv ob peb lo lo ntxhuav, tab sis tus nqi kuj yog siab. -precision txias-draw precision steel raj kom txuag tau hlau, txhim kho kev ua tau zoo, txuag lub zog Lub thiaj li hu ua high-precision txias-draw seamless steel raj yog hais txog qhov tseeb ntawm sab hauv thiab sab nraud qhov tseeb (qhov siab ntev) yog nruj, sab hauv thiab sab nrauv. tag, roundness, straightness, tuaj yeem txuag tau ntau lub sijhawm ua haujlwm, txhim kho cov khoom siv, thaum pab txhim kho cov khoom zoo.

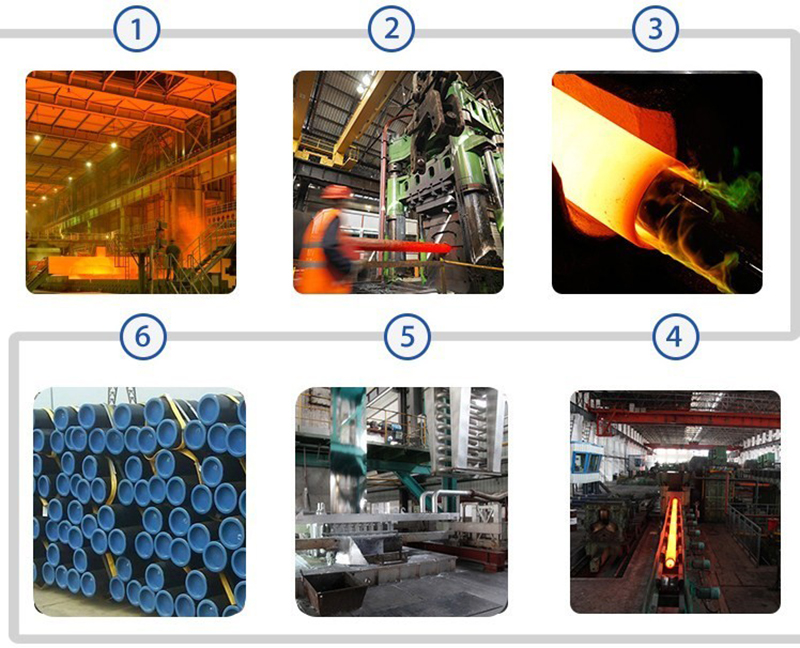

Cov txheej txheem txias txias tseem ceeb ntawm cov yeeb nkab steel yog qhov txias txias thiab txias dov txoj kev.Nyob rau hauv xyoo tas los no, nrog kev txhim kho ntawm kev tshawb fawb thiab thev naus laus zis, thiab kev tsim cov txheej txheem txias spinning, nrog rau txoj kev no tuaj yeem tsim txoj kab uas hla loj, high-precision txias-kuav los tiag raj thiab txias-kuav los tiag raj nrog kev sib txawv ntawm cross-section.Kev ua haujlwm txias ntawm cov yeeb nkab steel raw cov ntaub ntawv tuaj yeem yog kub dov seamless steel yeeb nkab tuaj yeem ua tau welded yeeb nkab.Cov yam ntxwv ntawm cov txheej txheem txias txias ntawm cov yeeb nkab steel yog qhov siab qhov tseeb, qhov zoo ntawm qhov roughness, tuaj yeem ua rau nyias nyias (txog 0.05 ~ 0.01mm) nyias-walled hlab thiab zoo heev (inch txog 0.3 ~ 0.1 hli) capillary. tubes.Seamless steel kav yog cov kav dej uas muaj hollow cross-section, uas yog siv los ua cov kav dej rau kev thauj mus los, xws li cov kav dej rau kev thauj cov roj, roj, roj, roj, dej thiab qee yam khoom siv.Piv nrog cov khoom siv hlau xws li cov hlau puag ncig, cov yeeb nkab steel yog qhov sib zog ntawm qhov hnyav thaum qhov khoov thiab lub zog torsional zoo ib yam, thiab yog ib qho kev lag luam hla cov hlau, uas yog siv dav hauv cov kav dej engineering.

Kev tsim khoom : Txheej txheem Round raj → cua sov → tho → peb-roller skew dov, nruam dov los yog extrusion → raj tshem tawm → loj (los yog txo) → txias → straightening → hydrostatic test (los yog flaw detection) → cim → cia seamless steel yeeb nkab Nws yog ua los ntawm steel ingots los yog cov tube khoom blanks los ntawm perforation los ua capillary hlab, thiab ces kub dov, txias dov los yog txias-draw.

1.Structural seamless yeeb nkab

(Seamless steel kav rau kev tsim cov kav dej, cov hlab ntsha, cov khoom siv, fittings thiab mechanical structures)

2.Seamless yeeb nkab rau cov kua hloov

(Cov kav dej uas siv los thauj cov kua dej yog cov kav dej thauj cov roj, cov nkev, roj, dej thiab qee yam khoom siv.)

3.Seamless raj rau boiler.

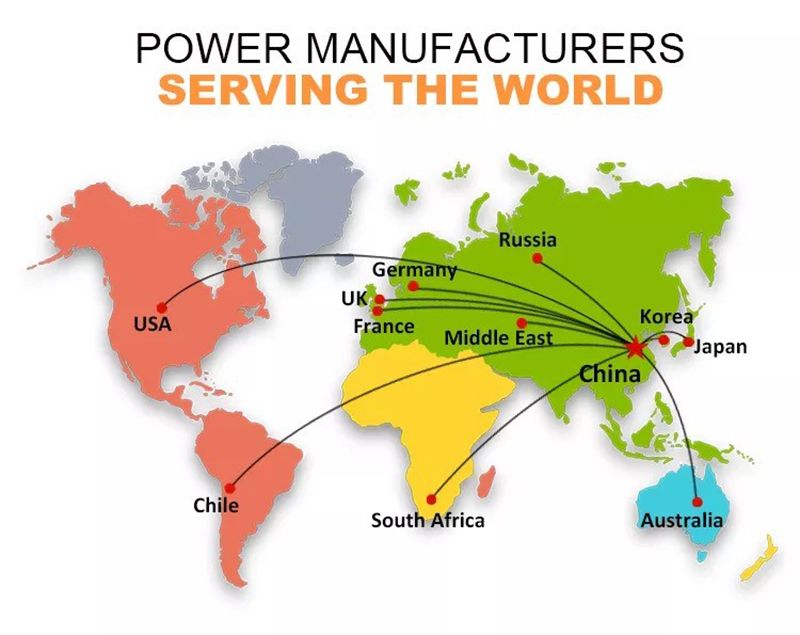

4. Conveying pipeline: Feem ntau yog siv rau kev xa dej, roj thiab roj.

5. Kab yeeb nkab: Feem ntau yog siv los tiv thaiv kab

6.Auto qhov chaw, hydraulic steel kav

1. Vim li cas koj xaiv peb?

Peb lub tuam txhab muaj 12 xyoos.Peb tswj cov khoom zoo nruj heev, muaj cov neeg tshwj xeeb rau qhov zoo.

Yog tias koj tau txais tus nqi qis dua los ntawm lwm tus neeg muag khoom, peb yuav them rov qab ob zaug rau cov neeg siv khoom txog tus nqi siab dua.

2. Koj lub sijhawm xa khoom ntev npaum li cas?

Raws li qhov kom muaj nuj nqis. Feem ntau nyob rau hauv 2-7 hnub yog nyob rau hauv Tshuag.Thiab 15-20 hnub yog tsis nyob rau hauv Tshuag.

3. Koj cov nqe lus them nqi yog dab tsi?

A: Los ntawm T / T 30% ua ntej, thiab 70% ua ntej xa khoom.

B: 100% L / C thaum pom.

C: Los ntawm T / T 30% ua ntej, thiab 70% L / C thaum pom.

4. Koj puas muab cov qauv?Puas yog dawb?

Yog lawm, peb muab cov qauv dawb tab sis tsis them tus nqi thauj khoom.

5. Yuav ua li cas yog tias tus neeg siv khoom tsis txaus siab?

Yog tias muaj teeb meem nrog cov khoom, peb ua lub luag haujlwm tag nrho.